0086-18362561302

Back to list

Back to list

Main features of the gluing machine (Description)

• The equipment is made of high-quality steel and proceed by the processing center. The continuous stability of the equipment is better than similar products, and the equipment can reach the leading level in the international industry.

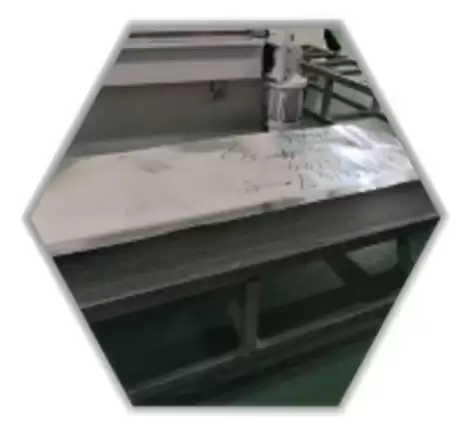

• Continuous and stable production can be achieved in the production process, with almost zero downtime, simple operation, one-key operation, cutting precision up to + 0.2mm, high-speed operation.

• The electric component adopts the international first-class brand, its guarantee the equipment movement is more. The electric component adopts the international first-class brand, its guarantee the equipment movement is more.

• Electric feeding device is adopted for feeding, which is efficient, safe, convenient and faster.

• The heating system adopts hot oil type and circulating air tunnel furnace drying system, which is safer, pollution-free, has a long service life and more uniform dying.

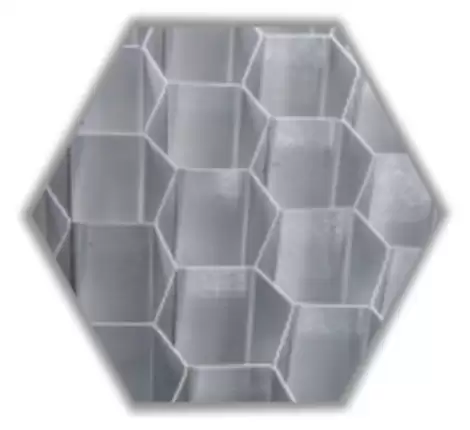

• Over 3mm side length can achieve automatic overlapping, reduce labor and save costs.

• The automatic glue supply and automatic glue regulating system is realized to reduce the number of manual glue addition, avoid solvent volatilization and prevent the instability of the product due to the large difference in viscosity of the adhesive.

Functional Show

|  |  |

Description | Unit | BHM-GP-AH600 |

Type | Automatic | |

Foil speed during gluing | m/min | ≤30 |

Oven temperature | oC | Room tem-180 |

Max glue roll width | mm | 600/914 |

Rubber roll width | mm | 600/914 |

Gluing printing roll circumference | mm | 480 |

Cutting precision (sheets length) | mm | ±2 |

Length | mm | 300 - infinite |

Width | mm | 600/914 |

Foil thickness range | mm | 0.035-0.2 |

Cell size | mm | ≥3.2 |

Power | kw | 30 |

Dimension | mm/kg | 9000*1500*2500/7000 |

Voltage | V/Hz | 380/50 |

Add WeChat to learn more