0086-18362561302

Back to list

Back to list

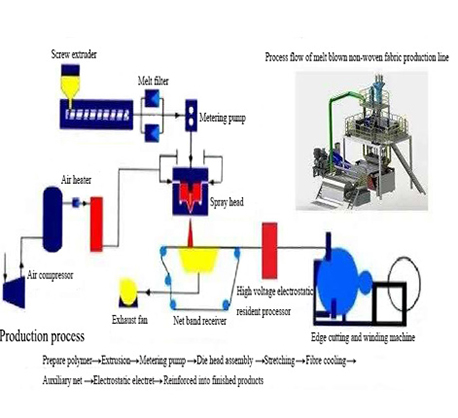

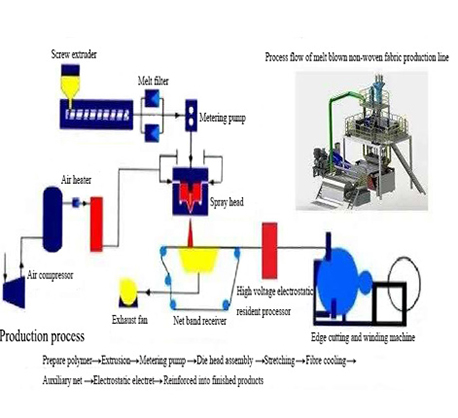

Equipment configuration list

Part name

• 5000 Watt variable frequency motor

• Automatic suction machine

• Dryer

• Melt filter

• 650Imported 650 spinneret

• Screw

• Air heater

• High voltage electrostatic resident processor

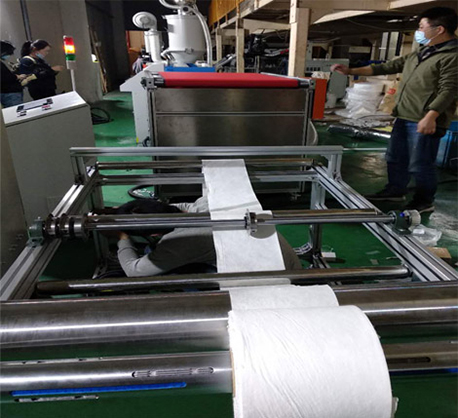

• Traction fabric forming equipment

• Adsorption cooling system

• Hob cutting

• Automatic winder

• Complete machine control cabinet

• PLCPLC system

Remarks:Customers need to add silver needle, air compressor, vacuum calciner, ultrasonic cleaner machine, better use effect.

Process flow of melt blown non-woven fabric production line

Competitive Advantage

• Equipment characteristics

• Imported core components

• High automation program

• High production efficiency

• Intelligent operation

• Capacity:400-500kg/24h

• Installation time: 1-2 days

• Manufacturing cycle: 10 days

• Site requirements: 3mx10m

• Size: 2000x9000

Add WeChat to learn more