0086-18362561302

Back to list

Back to list

Quick Detail

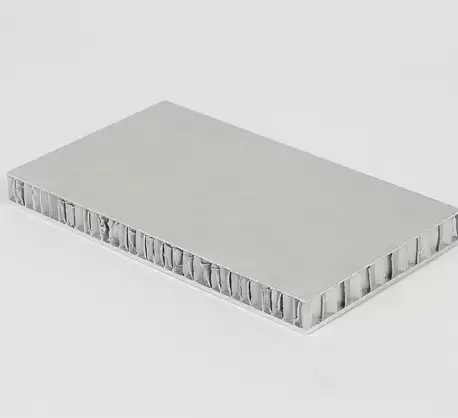

The aluminum honeycomb panel is composited of a honeycomb core sandwiched between two high tensile aluminum alloy sheets. These panels offer a higher strength-to-weight ratio than solid sheets, so they're often used as a lightweight alternative to solid aluminum.

Description

Anodized aluminum honeycomb panels take anodized AI-Mg Alloy as front skin and corrosion coated aluminum sheet as back skin, inside is aluminum honeycomb cores. All alloy used is 3003 series industry aluminum alloy.

Applications

• Gas piping, cables, building materials, etc

• Curtain wall decoration for buildings where security is important, such as airport, hospital and research center

• Curtain wallboards for outside walls of normal buildings

• Renovations for old buildings and movable houses

• Reformation and decoration for indoor wall, ceiling, bathroom, kitchen and balcony

• Facades

• Billboards, exhibition desks and notice boards

• Wallboards and ceilings for tunnels

• Materials for industrial application, car and ship bodies

Competitive Advantage

• New, modern and beautiful building materials

Anodizing process is different from ordinary aluminum painting process. Anodizing process electrolyzing the conductive acid electrolyte through electric current to make the aluminum surface anodized and produce a dense protective oxide film. The oxide film is not additional like painting, it will not fall out.

• Safe, energy saving and recyclable

The anodized protective film is a kind of inorganic substance without any harmful articles. It is also non-combustible materials and 100% recyclable, so it is not safe to use but also energy saving.

• Easy to clean and maintain

The anodized aluminum honeycomb surface is anti-pollution and weather resistance. The special component of the oxide protective film makes the honeycomb panel surface free from dust and fingerprint.

• BEECORE Honeycomb Composite Panel manufactured by Jiangsu Beecore in Taizhou obtained certification to Bonding Standard DIN 6701 A2, the accreditation for the use of adhesive bonding in the manufacture of rail vehicles and parts of rail vehicles.

Thickness of aluminum sheet | 0.5-1mm or customized |

Honeycomb panel thickness | 10-25mm or customized |

Panel width | 1220mm,1550mm or customized |

Panel length | 2440mm or customized |

Color | Natural, White or as requested |

Surface finished | Anodizing |

Add WeChat to learn more